Reciprocating Compressor s and Its types

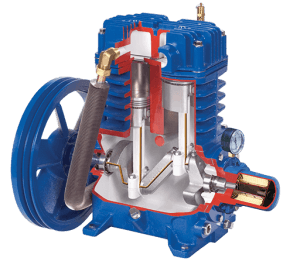

This type of compressor uses a piston-cylinder arrangement to compress the air. Whenever something moves back and forth it’s considered as occupancy Reciprocating Compressor.

Similarly, during this type piston pull away and forth inside the cylinder and compress the air.

Engineering – The reciprocating compressor takes inside the successive amount of volume of air from the valve and confined it in the closed surface at that point piston moves downward with the closure of the valve. Then there’s compression of air by reducing its volume. Now the piston moves upward and compresses the air then displace the compressed gas through the valve. And then again intake occurs and the cycle repeats itself.

This type of reciprocating compressor also called positive displacement machines. They are available in both as lubricated and oil-free.

The reciprocating compressor is single acting when the compressing is accomplished using just one side of the piston and double-acting when both the perimeters of the piston used.

Applications

The reciprocating compressor generally saw where there’s a requirement of air mass and low flow(or discontinuous flow up to 30 bars). Mostly where the air is employed for hand-tools, cleaning dust, small paint jobs, commercial uses, etc.

Types of Reciprocating compressor

Single-acting

they are the reciprocating compressor which has piston working only in one direction. The other end of the piston is commonly free or open from which no work is performed. There is only 1 side compression or the upper a part of the piston is employed to compress the air. the bottom part is a hospitable crankcase and isn’t utilized for the compression of air.

Double acting

As from its name it uses its every side to compress the air. These styles of compressors have two sets of suction/intake and delivery/exhaust valve on either side of the piston. As the piston moves up and down, both sides of the piston are employed in compressing the air. The intake and valve operate such as the movement of the piston or with the stroke of the compressor. The air is compressed accordingly and delivered continuously as compared to a single-acting compressor. Here both sides are effectively used for compressing the air.

Inline Compressors

Its name clarifies the planning of the compressor. The cylinders of varying stages are found in a very line when seen from the highest that’s why they’re called inline compressors. These are most ordinarily used compressors within the area where there’s a necessity of varying pressure. They have a simple design and commonly driven by electric motors or diesel engines.

V-shaped compressors

They come under air-cooled compressors with concentric valves mounted on each plate unit which are placed in V-shaped i.e. at the angle of 90 degrees from one another and will or might not be connected to the same crankpin on the crankshaft.

They are compressors of upper capacity therefore the cooling is required. The v-shaped is given to such a compressor for achieving better torque and balancing by displacing different units at some angle.